Metal Composite Panel Production Line

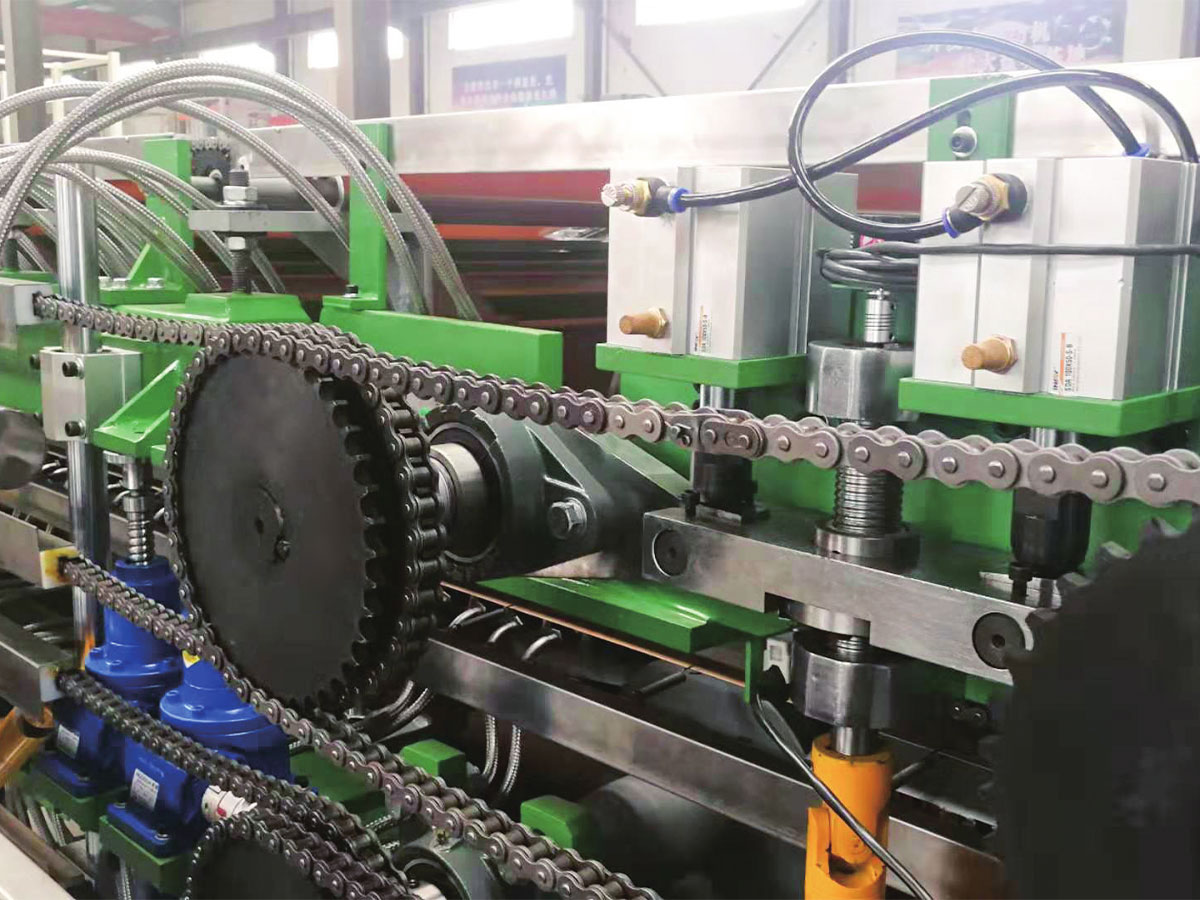

The metal composite panel production line is a large-scale automated equipment system specifically designed for the production of "metal composite panels." Its function is to firmly and precisely combine two (or more) disparate materials to create a single sheet with multiple advantages.

This production line integrates mechanical engineering, automated control, materials science, and heat treatment processes, making it a representative example of technology-intensive manufacturing.

Laminating precious metals with common substrates ensures product performance and reduces material costs.

Large-scale continuous production significantly improves production efficiency, meeting market demand for large-scale composite panels.

Precise process control ensures stable and consistent product quality, providing reliable support for downstream applications.

The system encompasses a complete process, including unwinding, cleaning, laminating, laminating, curing, and finishing. Each link is equipped with sophisticated control systems to ensure accurate and stable production.

-

The PE/B1 aluminum-plastic composite panel production line uses a thermal lamination process to firmly bond the surface ...View More

The PE/B1 aluminum-plastic composite panel production line uses a thermal lamination process to firmly bond the surface ...View More -

In 2012, we independently developed the A2 Metal Composite Panel Production Line, a second-generation continuous laminat...View More

In 2012, we independently developed the A2 Metal Composite Panel Production Line, a second-generation continuous laminat...View More -

In the field of modern building and decorative materials, market demand for fire safety and versatility is increasing. O...View More

In the field of modern building and decorative materials, market demand for fire safety and versatility is increasing. O...View More -

The core technology of the 3D board/corrugated board/honeycomb panel composite production line lies in its dedicated com...View More

The core technology of the 3D board/corrugated board/honeycomb panel composite production line lies in its dedicated com...View More -

Bimetallic cladding production lines utilize advanced process technology to firmly bond two metals with different proper...View More

Bimetallic cladding production lines utilize advanced process technology to firmly bond two metals with different proper...View More

*E-mail: [email protected]

English

English